Our safety rating, or Experience Modification Rate (EMR), is calculated by comparing our claims history and safety record to other businesses in the same industry and the same state.

At Tate, we’re proud to have achieved an all-time low EMR rating of 0.66 in 2025, reflecting our unwavering commitment to safety. For the past five years, we have maintained an extremely favorable and highly regarded low EMR, at or below 0.69. This achievement is the result of a robust safety plan, actionable improvements, and rigorous, continuous training. Safety remains at the core of everything we do, and we strive to meet the highest safety standards every day.

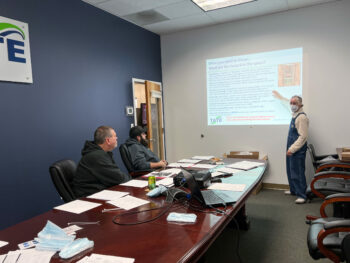

Our commitment to continued training is vital to our organization, enabling us to maintain our outstanding safety record. By prioritizing regular training and development for our employees, we ensure that they are equipped with the necessary knowledge and skills to maintain a safe working environment.

Safety is our utmost priority, and we understand that a well-trained workforce is essential in preventing accidents and ensuring the well-being of our employees and facilities. Through ongoing training programs, we aim to enhance the competency and awareness of our workforce in identifying and addressing potential risks.

In addition to this, our focus on safety has helped us decrease our insurance rates, annually lower our EMR and solidify strong partnerships with our customers that ensure the safety of their people and property. It has also generated significant operational savings, giving Tate a real market advantage over the competition.

The mechanical systems we install and maintain are not only powerfully effective, but also require powerful safety measures.

We have a rigorous safety program in place to ensure our clients (and theirs) the utmost in safety. Our comprehensive training aligns with the regulatory guidance of MOSH, VOSH, OSHA, EM 385, EPA, DOT, FMCSR and MSHA.

Safety is a steady mission. Our service teams consistently undergo cross-functional safety training to maintain up-to-date certifications, and are equipped to handle all of the various systems we offer. We also offer on-site customer training to ensure that you know the nuances of your particular mechanical system and understand its safe operation. Finally, our Quality Assurance Department consistently checks client facilities and reviews safety procedures to deliver ongoing, continuous improvement.